Product Category

Contact Us

Phone:

86-577-86569666/85986466

Fax: 86-577-85888877

Email: zgkk@zgkkv.com

Agent Hotline: 86-18523831111

Three Eccentric Multi-level Hard Seal Butterfly Valve

Key words:

Classification:

Keyword: Three Eccentric Multi-level Hard Seal Butterfly Valve

E-mail:

Details

Our products now cover a wide range of standardized fluid control products that can be adapted to a variety of drive modes, comprising ball valves, butterfly valves, gate valves, globe valves, check valves, safety valves, rotary ball valves, plunger valves etc. Our products are widely used in water conservancy, municipal, electric power, gas, petrochemical, coal chemical, energy, environmental protection, medicine, real estate, metallurgy, mining and many other fields.

Feature

1. butterfly plate seal for the hard and soft layering pieces of metal with a metal seal and flexible seal the dual advantage of both low and high temperature cases, both with excellent sealing perfomance.

2.using three-dimensional eccentric structure,valve seat and butter-fyplate almost no ficion,with the more closed more tight sealing function.

3.valve sealing surface,using welding stainless steel,cobalt-based alloy,sealing surface wear resistance and long service life.

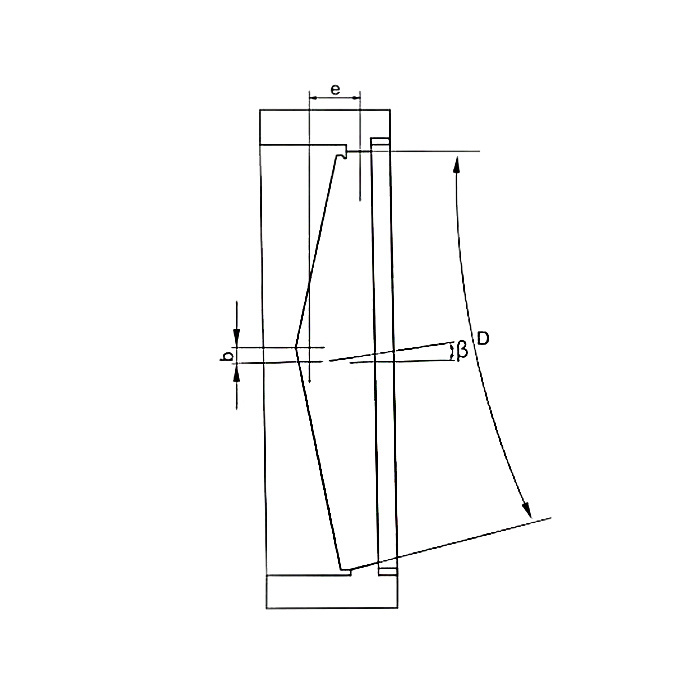

4.The stucture is uniue,the operaton nimbe,reduces effot con-venieny,the medium pressure hich,the low influence,the sealing propety not to be umrelable,the service life is long.The usual double eccentric buttefly valve,as b(devate from the pipe center) and a (devate from the sealing surface of the centeline) as shown in the aim of reducing valve seat and seal betwen the friction of appro-ximately 15°tavel.HPV adds a unique eccentric anglep,slope of the cone not only overcome the valve open and close the valve open and close the seal and the seat all contacts betweenthe friction,thereby increasing the service life,but also throngh changes in torque can be applied arbitrarily to adjust their seal over pressure,si that more reliable seal and never pass phenomenon occurs.

Standard

| Manufacturing Standard | JB/T8527-2015 |

| Structure the length of the standard GB | GB12221-2005 |

| Flange Standard | GB9113-2010 |

| Test Standard | GB/T 13927-2008 |

Main Performance Specifications

| DN | DN(mm) | 50~2000 | 50~500 | |||

| PN | PN(MPa) | 0.6 | 1 | 1.6 | 2.5 | 4.0 |

| Test Pressure | Strength test | 0.9 | 1.5 | 2.4 | 3.8 | 6.0 |

| Seal test | 0.66 | 1.1 | 1.8 | 2.8 | 4.4 | |

| Gas seal test | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Leakaae rate | <0.1xDNmm/s(in line with GB/T 13927-2008 standard) | |||||

| Leakage rate | Carbon steel,chrome molybdenum steel:-40℃~550℃ | |||||

| Applicable medium | Air,water,steam,gas,oil and acid,alkali,salt with a weal corrosive media,etc. | |||||

| Drive type | Worm wom transmission,electric transmission | |||||

Main Components Material

| Part name | Material |

| Body | Carbon steel,stainless steel,chrome molybdenum steel,alloy steel |

| Disc | stainless steel,chrome molybdenum steel,Carbon steel,alloy steel |

| Sealing ring | Stainless steel and high temperatureasbestos combined inito mulfi-level |

| Stem | Cr13 Series Stainless Steel,Austrian Stainless Steel and Alloy Steel |

| Bearing | Austenitic stainless steel,304 nitride |

| Packing | Flexible graphite |

Related Products

Message

*Leave your contact information to get a free product quote